Capture and Retain Reason Code (RC) history for a Process of Ongoing Improvement.

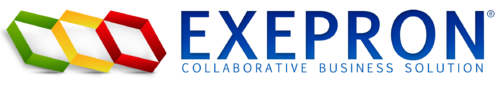

The RC Chart provides an accumulation of the reasons for Task Delays.

Capturing the Reasons that cause the “most delays, on most projects, most of the time?”

The build-up of RCs history creates the RC Chart and Pareto Analysis for addressing the highest source of accumulated delays.

See Portfolio Dashboard / Reports / Reason Code Report

In this example above, the “Material Defect” is the highest reason for delay.

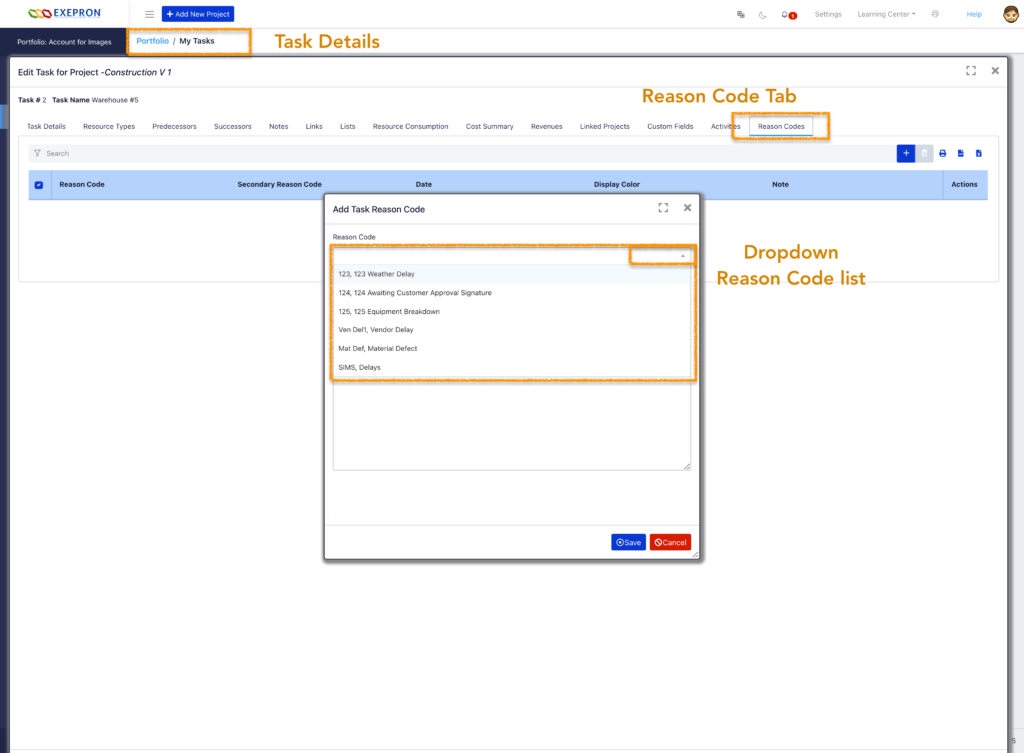

Exepron encourages Supervisors, Task Managers, and Resources to add a Reason Code for Task delays when updating a delayed Task.

Project Managers and the Portfolio Management Office should create a standard set of RCs for your Organization.

Users updating delayed Tasks, and in the Task Details Screen, can click and apply the Std. Reson Codes for the delays.

Over time PMOs should track the impact of improvement processes by addressing the highest instance of Reason Codes for delays.