In Project Management, it is common for Tasks to exceed their planned duration due to various factors. To analyze and address these delays effectively, it is essential to understand the reasons behind them. This guide aims to assist Project Managers and Team Members in correlating the Reason Codes for delays recorded against project tasks.

Process of Ongoing Improvement

By leveraging the history of reasons for delays, users can identify patterns, take preventive measures, and improve future project performance. Improvements should be built into the existing Templates and Templates Blocks for immediate best practice use on future projects.

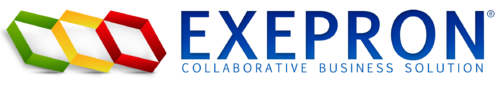

Familiarize Yourself with Reason Codes #

-

- Reason codes are predefined categories or labels used to identify the causes of delays in project management tasks.

- They provide a standardized way of documenting and categorizing reasons for delays.

- Create and review an existing list of Reason Codes used in your project management environment.

- Ensure that the Reason Codes cover a broad range of potential delay causes and are well-defined and easy to understand.

Capture Reason Codes for Delays #

-

- Encourage project team members to record Reason Codes for delays against each task.

- Recordings should be done promptly and accurately as part of the Daily Task updating to ensure data integrity.

Exepron maintains the Reason Code History #

-

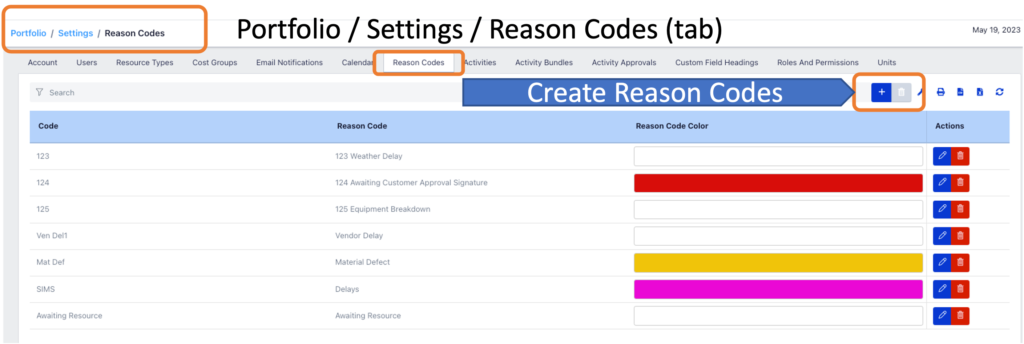

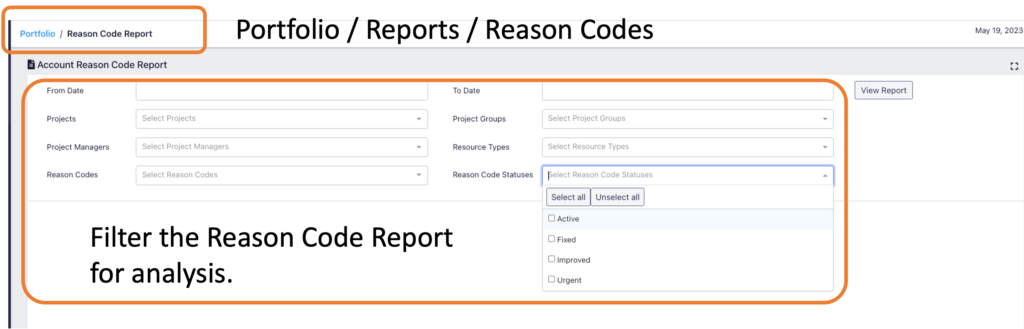

- Exepron retains the history of reason codes for delays.

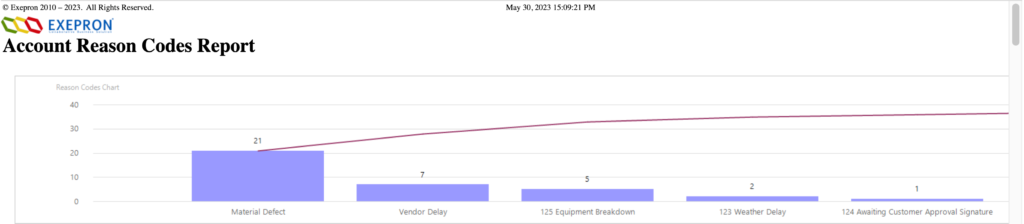

- To review and manage the historic Summary in a Pareto Chart and the data, visit: Portfolio / Reports / Reason Codes.

Analyze Reason Code Patterns #

-

- Periodically review the reason code history in Exepron’s Pareto Chart to identify recurring patterns or trends in the reasons for delays.

- Look for commonalities in the types of delays and the corresponding reason codes.

- This analysis can help you identify root causes and take proactive measures to prevent similar delays in the future.

- Filter to View – Active, Fixed, Improved, Urgent Reason Code Items.

Note: Without selection, All Reason Code Statuses will display.

Review the Pareto Chart of Reason Code History #

Continuous Improvement #

- Act on the insights gained from the correlation analysis. Develop strategies, processes, or training programs to proactively address the identified delay causes.

- Monitor the effectiveness of the implemented improvements and measure the impact on reducing delays.

- Continuously refine the Reason Code list based on lessons learned and emerging delay causes to ensure its relevance over time.

Summary #

Correlating the delay Reason Codes recorded on project tasks enables project managers and team members to gain valuable insights into the causes of delays and take appropriate actions. By maintaining a comprehensive reason code history and analyzing patterns and correlations, you can make informed decisions, improve project planning, and enhance overall project performance. Remember to continuously review and update the reason code list to capture emerging causes of delays and promote continuous improvement in your project management practices.